Welcome back to Decouple. This week, we talk tools.

With precision machinist Noah Rettberg, we explore a facet of modernity arguably as important as energy, for it is the technology that energy powers and the technology that makes that technology: machine tools. Noah draws from his professional knowledge and passion for history to take us from Roman metallurgy through the guild-protected craftsmanship of medieval Europe to the steam-powered revolution in machining to the cutting edge of modern metalworking tools. Riveting!

Watch the full interview on YouTube.

We Talk About

The pivotal role of metalworking in enabling industrialization

Why ancient civilizations didn’t embrace steam power

The critical difference between plentiful labor and scarce craftsmanship

Denis Papin’s early steam engine, sabotaged by guild workers

Thomas Newcomen’s practical steam engine solutions

Guilds, apprenticeships, and the esoteric transmission of technical knowledge

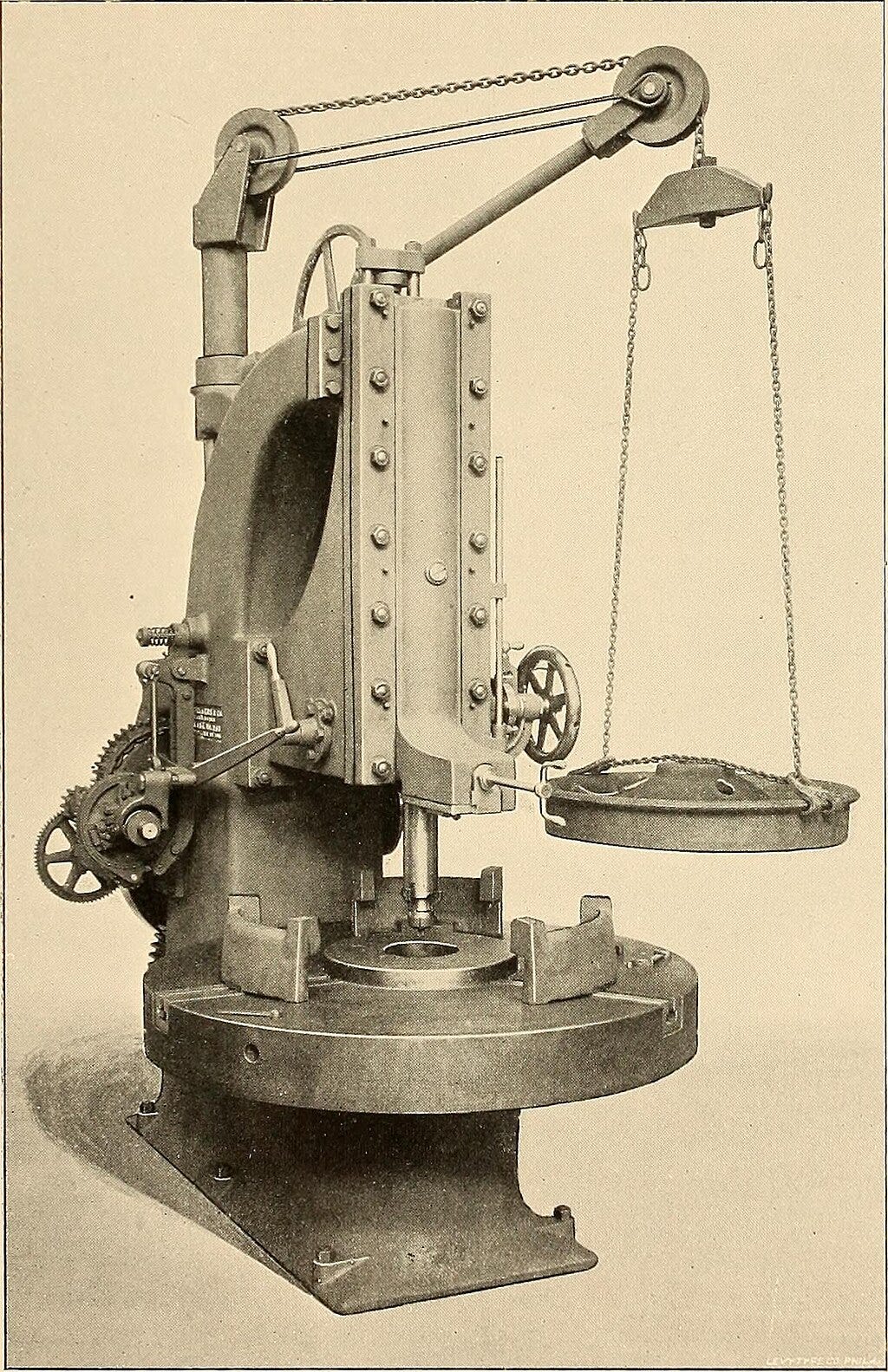

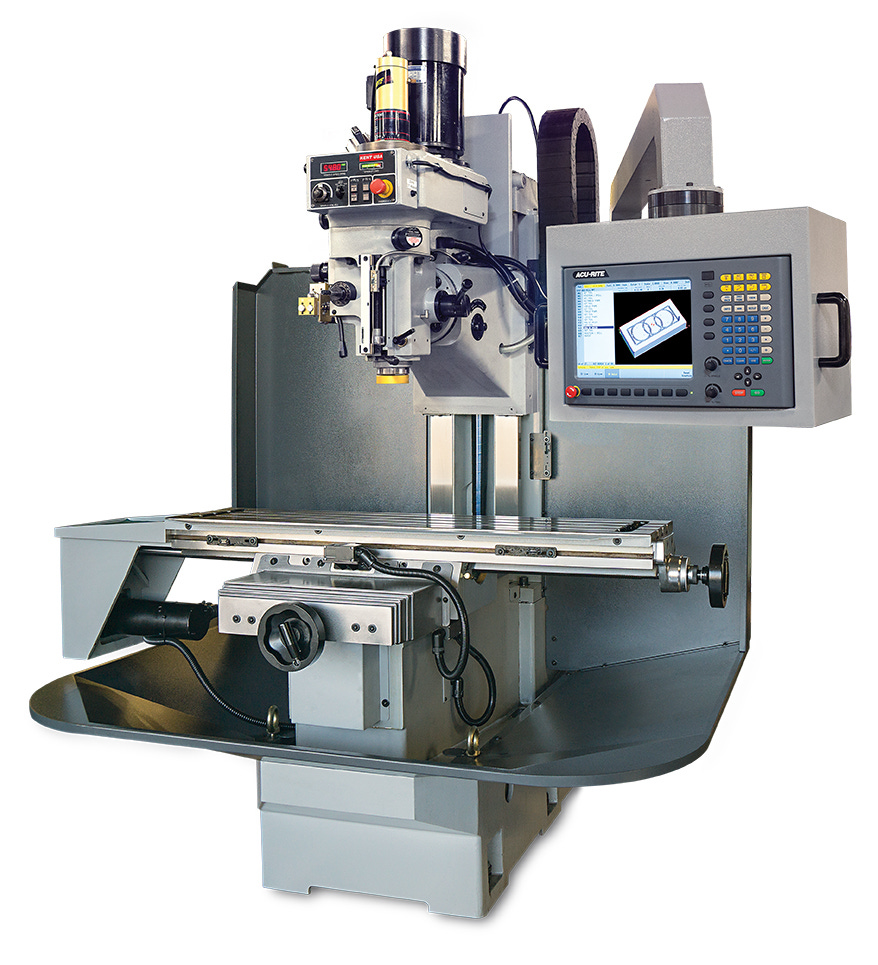

Machining technology from Roman screws to modern computer numerical control (CNC) machines

The synergy between energy resources, metalworking technology, and economic incentives

Why Britain, rather than France or Germany, launched the Industrial Revolution

Modern CNC machining and Germany’s ongoing global dominance in precision tool-making

The geopolitical significance of tool-making capabilities today

Deeper Dive

When the Romans ruled, metal was precious. Emperor Trajan’s empire thrived with abundant human labor but scarce skilled craftsmen. Metal tools were luxuries—reserved only for tasks demanding precision like shaping temple stones. Noah argues that Trajan, despite his power, would have laughed away plans for a steam-powered boat; human rowers were plentiful and cheap. Yet, hidden in the intricate screws and dials they created, Roman craftsmen laid seeds for an eventual technological bloom.

Centuries later, Denis Papin, a Protestant physicist exiled from France, attempted to harness steam power. His ambitions were bold, crafting a steam engine to propel boats upstream. But Papin faced a double tragedy: metalworkers unaccustomed to precise components, and guildsmen who feared machines would replace their livelihoods. They smashed his engines, forcing him into poverty. Papin’s tragedy illustrates how human resistance and skill scarcity limited innovation long before machines reshaped society.

The real revolution began quietly in British coal mines. Thomas Newcomen saw what Papin did not: steam engines belonged where fuel was abundant and human labor costly. Britain, with fewer guild restrictions and a centralized economy, provided the craftsmen and resources necessary. Newcomen’s engines drained mines, boosting coal extraction and making steam viable. Here was the true birth of the Industrial Revolution—where energy, human skill, and economic demand merged.

Precision metalworking then advanced rapidly. Craftsmen’s guilds spread esoteric knowledge from master to apprentice, transforming isolated skill into collective expertise. With steam power driving machines that replaced laborious handwork, productivity exploded.

“The steam engine allows you to bring power to the table. Machine tools bring precision.”

Mills, lathes, and planers allowed precise metal parts—previously painstakingly handmade—to be mass-produced. This unlocked a new level of productivity: machines creating machines that multiplied human efforts exponentially.

Today, Germany and Japan dominate global tool-making, rooted deeply in cultural traditions of craftsmanship. Precision machining remains partly esoteric, a protected reservoir of knowledge transferred through generations. As global tensions rise and trade barriers return, control of tool-making expertise becomes geopolitically critical. Nations unable to manufacture their own advanced machinery risk dependency. Russia's struggles after sanctions, dependent on German precision, underscore this vulnerability.

Precision machining, often invisible, has always quietly driven human progress. From Roman screws to CNC machines, metalworkers have crafted the improbable objects that transform societies. Among the most transformative of these objects have been the machines that build more machines.

If you found this conversation as riveting as we did, consider making a pledge on Substack or a tax-deductible donation through our fiscal sponsor.

Keywords

Precision machining, metalworking, steam engine, Industrial Revolution, Denis Papin, Thomas Newcomen, CNC machines, apprenticeship, productivity, geopolitics