This week, we return to nuclear power. Specifically, nuclear construction and “learning curves.” It is intuitive that doing something over and over makes you better at it. In industry, this means driving down costs and timelines and boosting efficiencies. In many industries, the truth of learning curves is readily apparent. However, in Western nuclear construction it has been largely absent for decades. Robbie Stewart, CTO of Alva Energy, joins me to dissect why the nuclear industry struggles with what other industries take for granted, and highlight a few cases in nuclear that managed to buck this trend. From France's standardized reactor fleet to China's recent AP1000 acceleration, we explore the prerequisites for nuclear construction learning and why it takes more than just good engineering.

Watch now on YouTube.

We Talk About

Wright's Law and its application (or misapplication) to nuclear construction

Why nuclear is fundamentally different from factory-floor manufacturing

The three categories of nuclear learning: fixing mismanagement, technology insertion, and construction optimization

Statistical analysis of what drives successful learning rates in nuclear programs

France's P4 series and South Korea's OPR-1000 as learning success stories

China's dramatic improvements in AP1000 construction times through supply chain mastery

The critical role of integrated project management and utility ownership

Prerequisites for learning: standardized design, sequential builds, and institutional commitment

Why inter-site learning is harder than intra-site learning

The developer model as a potential solution for geographic learning constraints

Ontario's SMR program as a test case for modern nuclear learning

Deeper Dive

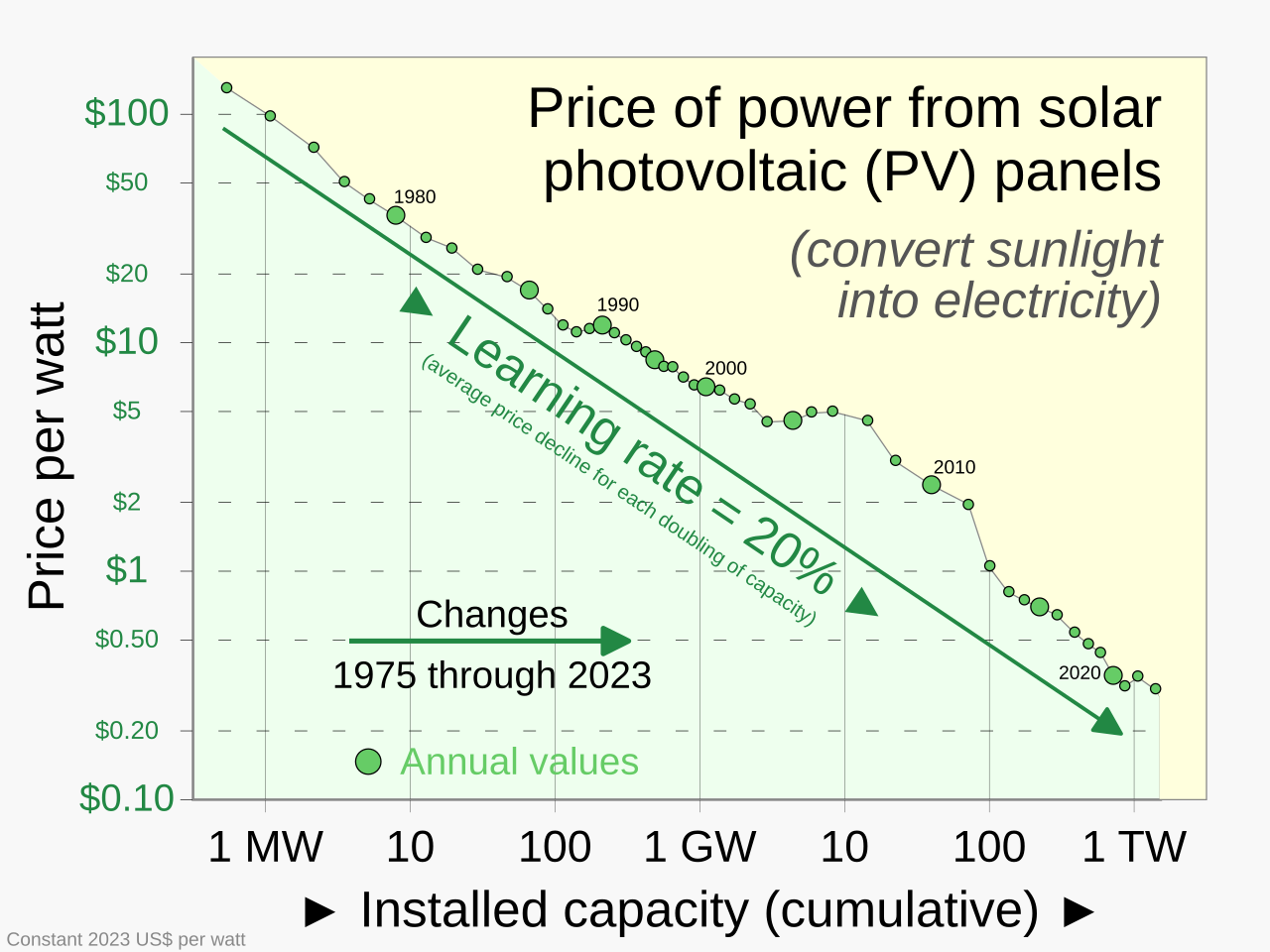

Getting better at building nuclear plants isn't only, or even mostly, about nuclear engineering. It's about project management, supply chains, and institutional memory. Stewart introduces us to Wright's Law—the phenomenon where costs drop by a predictable percentage with each doubling of production—which has transformed industries from aviation to solar panels. But nuclear construction has largely resisted this "iron law" of manufacturing improvement.

Stewart breaks nuclear learning into three distinct categories, and only one resembles traditional Wright's Law improvements:

The first bucket is simply "solving the mismanagement mess." Eliminating the thousands of design changes that plagued recent builds like Finland's Olkiluoto unit 3 or Georgia's Vogtle units. This isn't innovation as much as basic project execution.

The second category involves actual technology insertion, like the automatic welding systems deployed at Japan's Kashiwazaki-Kariwa plants or the slip-forming techniques that accelerated containment construction at St. Lucie 2.

The third category represents true Wright's Law learning: factory-floor improvements in component fabrication and supply chain efficiency.

What makes nuclear different from other industries becomes clear when examining programs that have gone right. Statistical analysis by researchers like Berthélemy and Rangel reveals three key predictors of nuclear learning success: electricity demand growth rates, the number of reactors under construction simultaneously, and whether utilities maintained integrated architect-engineer capabilities. Countries desperately needing power (like France during the 1970s oil crises) mobilized resources in ways that created true institutional momentum. Multiple simultaneous builds created ecosystem effects, supporting specialized supply chains and experienced construction crews. Most importantly, utilities that kept engineering in-house could see and control every detail of their projects.

The French experience with their P4 reactor series demonstrates how standardization enables learning. Building thirty units of essentially the same 900-megawatt design created the demand certainty that suppliers needed to invest in efficient fabrication methods. But even here, the learning curve flattened after the first few builds. Stewart's research shows about 20% cost reduction from first-of-a-kind to end-of-series, then costs stabilize. The dramatic improvements come from eliminating first-of-a-kind chaos, not from endless optimization.

China's recent acceleration of AP1000 construction offers the most compelling modern example of nuclear learning in action. After struggling through nine-year builds for their first AP1000 units—times comparable to the troubled U.S. experience—Chinese builders have cut construction schedules to 54 months for newer units. Stewart's analysis of module placement data shows some components being installed 75% faster than in first builds. This is supply chain mastery and institutional learning on full display. By indigenizing component fabrication and eliminating foreign supply chain delays, China solved the "mismanagement bucket" of learning challenges.

The prerequisites for nuclear learning emerge clearly from successful programs: standardized designs, sequential builds with time for iteration, and institutions committed to capturing and transferring knowledge. The most successful projects, like TEPCO's relatively quick construction of ABWR reactors at Kashiwazaki-Kariwa, leveraged site experience across different reactor types. That first-of-a-kind advanced reactor was actually the fastest build at the site because the utility, constructor, and supply chain had already learned project execution through previous builds.

But nuclear learning faces a geographic challenge that other industries don't. Unlike solar panel factories that can ship products globally, nuclear construction knowledge lives in people's heads and organizational procedures. Moving that expertise between sites means moving teams, families, and institutional culture. The developer model emerging in today's market attempts to solve this by creating organizations dedicated to building multiple plants across different locations, institutionalizing the knowledge transfer that utilities constrained to single service territories cannot achieve.

“The upside here is so huge that compensating people to move to the site is trivial in the grand scheme of the total.” – Robbie Stewart

Ontario's upcoming SMR program at Darlington will provide a real-time test of these principles. The plan to build one unit, capture lessons learned, then build three more in parallel represents a textbook sequential learning strategy. But the real test will be whether that site-specific learning can transfer to other provinces or international markets—the challenge that has historically limited nuclear learning to national programs with strong institutional continuity.

The stakes extend beyond individual projects. As Stewart puts it, whoever figures out learning rates and cost reduction for standardized nuclear designs will capture most of the value in the industry's future.

The nuclear industry's transition from operational excellence to construction excellence may determine whether nuclear power can scale to meet climate and energy goals or remain a boutique technology for wealthy countries with patient capital.

Support Decouple Media

If you find Decouple Media a useful part of your information diet, please consider support us through a Substack pledge or a tax-deductible donation through our fiscal sponsor. Thank you!

Keywords

Wright's Law, nuclear learning rates, standardized reactor design, construction optimization, supply chain integration, project management, institutional knowledge, sequential builds, China AP1000, nuclear construction costs