By Chris Keefer | November 2025 | Decouple Media

Living inside the “next chapter”

Two years ago on Decouple, James Krellenstein and I recorded an episode with an aspirational title: American Nuclear, the Next Chapter. At the time it felt more like wishful thinking than reportage.

The conversation took place in a different climate. Investors and policymakers were fixated on small modular reactors, microreactors, heat pipes, and HALEU fuel. The “spaceX of nuclear” was a stock phrase. High profile people argued that a handful of lightly resourced startups would do for reactors what commercial launch companies did for rockets.

James ended that first episode with a prediction that sounded eccentric, if not slightly reactionary. If the United States wanted real new nuclear on the grid in the near term, he said, it should focus on building AP1000s and other existing large light water reactors like the ABWR in fleet mode, not chase vaporous concepts.

That was 2023.

In 2025 the picture looks different.

Vogtle 3 and 4 are finally online. Santee Cooper has selected Brookfield to complete construction of the unfinished AP1000 units at V.C. Summer, and perhaps most significantly the Trump administration has announced an $80 billion strategic partnership with Westinghouse to support the construction of new AP1000 reactors across the USA.

Three Mile Island Unit 1, an emblem of nuclear’s supposed decline, is back under a premium power purchase agreement with Microsoft. Data centers, cloud providers, and industrials are quietly telling developers what they actually want.

They are not buying “advanced nuclear” as a concept. They are buying high capacity factor megawatt hours and AP1000 is the only commercial scale Gen 3 plus reactor that can plausibly deliver those megawatt hours reliably on the first unit.

The Reliability Premium

The starting point for James’s argument is brutally simple: the market has re-discovered the value of a machine that runs near continuously.

Solar capital costs have fallen, storage costs have fallen, and for a 30 or 40 percent capacity factor you can carpet land with panels at a fraction of nuclear’s upfront bill. If all you want is energy some of the time, the toolkit is large.

What the last decade has demonstrated very clearly is that this does not solve the problem faced by hyperscale data centers and modern grids. They are not buying annual averages. They are buying 24/7 power.

That has two consequences.

First, there is now a genuine premium for high capacity factor energy. The Microsoft contract at Three Mile Island is a visible example, but similar deals are proliferating off stage. The buyers are sophisticated and willing to pay two, three, or four times wholesale prices for firm, clean megawatt hours.

Second, that premium is only justified if the technology can actually stay on 24/7/365.

Here the historical record is not kind to so called “advanced” reactor concepts.

Germany’s tiny 15MWe AVR pebble bed reactor, after years of operation, reached roughly a 62 percent capacity factor.

France’s 250MWe Phénix sodium fast reactor hovered around 40 percent, while 1242MWe Superphénix, the flagship, spent its short life near single digits.

Fort St. Vrain, the 330MWe prismatic high temperature gas reactor in Colorado, averaged close to 15 percent capacity factor, a level that genuinely could have been beaten by solar on the same site.

The unplanned outages that plague these “next generation” reactors, especially when scaled up in size, are particularly punishing for nuclear economics because the capital is sunk and the meter never stops running, while at least renewables are reliably unreliable, their variability is baked into project finance rather than blowing up the budget mid-stream.

By contrast, the mature American light water fleet, after many decades of trial and error, now runs at about 93 percent capacity factor on average. That is what is being monetized in these new contracts.

If your business proposition to a Microsoft, an Amazon, or a metals producer is “I can give you 90 percent plus capacity factor for decades”, then the technology has to be battle tested and more than a rendering. It has to carry industrial memory.

Among all the new reactor types vying for attention, only the AP1000 has any credible claim to that inheritance.

A “cafeteria” reactor built from proven parts

The paradox of the AP1000 is that it is called “advanced” in public discourse, but the nuclear steam supply system is intentionally conservative.

James describes it as a cafeteria reactor. Westinghouse did not attempt to reinvent the core, the coolant, or the thermo-hydraulics. Instead, it took the best proven elements from its own light water fleet and from the Combustion Engineering line, and recombined them in a way that would be familiar to any PWR engineer of the last forty years.

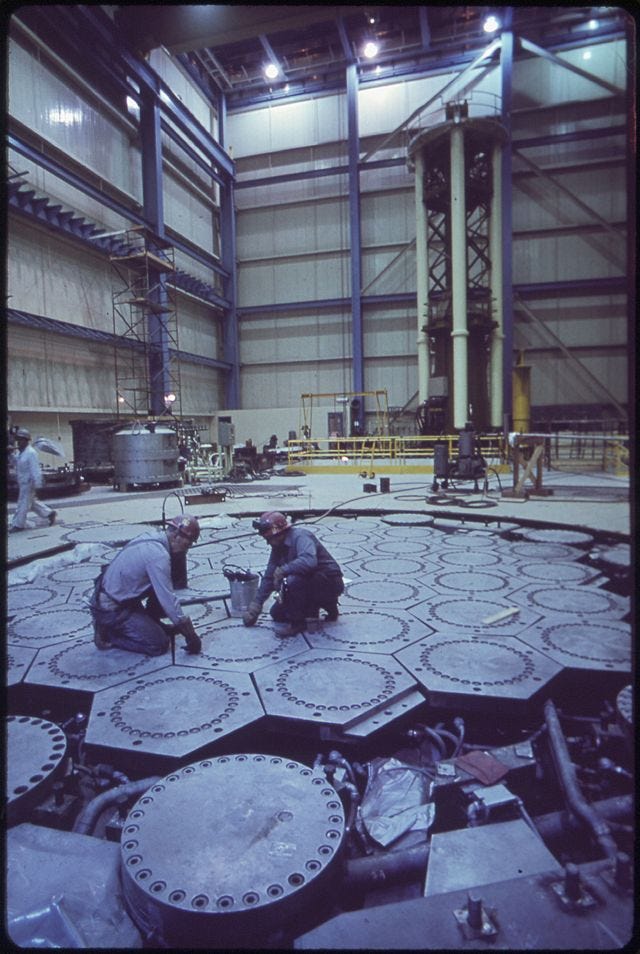

At the heart of the AP1000 lies a 157 fuel assembly core. The core geometry would be instantly recognisable to anyone who has worked on classic Westinghouse three loop plants. The main change is length. Instead of the more common twelve feet of active fuel, the AP1000 uses fourteen foot fuel assemblies, borrowing from designs such as South Texas Project, European plants like Doel and Tihange and any Combustion-Engineering System 80 core.

Move outward and the same pattern appears.

The steam generators are direct descendants of the CE “Delta 125” units at Arkansas Nuclear One Unit 2, updated but firmly within that lineage.

The pressurizer volume is comparable to South Texas Project, giving the AP1000 more margin for pressure and level transients than earlier designs.

The core barrel design tracks back to Waterford 3 and the broader CE family.

Even the hydraulic layout, a two loop arrangement with two reactor coolant pumps per steam generator, sits comfortably inside the range of existing practice.

In other words, the daily workhorse of the plant, the nuclear steam supply system that turns fissile heat into steam, is not radically new. It is a stitched together best of set drawn from thousands of reactor years of operation.

This is why units such as Sanmen and Haiyang in China, once they were finally completed, rapidly became some of the most reliable performers in the Chinese PWR fleet. It is why Vogtle’s units, whatever one thinks of the construction saga, are now slotting into the grid without commissioning dramas.

So if the AP1000 is conservative where it makes steam, where is the innovation?

AP600 to AP1000: innovating in the right place

The short answer is that Westinghouse innovated in the safety systems, partly to improve the safety case but primarily with the cost reduction motive of removing high CAPEX/OPEX active safety systems.

The AP600 came first, designed in the 1990s as a 600 megawatt electric plant with fully passive safety. No safety grade AC power. No safety critical emergency diesel generators. The design relied on gravity, large tanks of water, natural circulation, and clever thermodynamics rather than on motor driven pumps.

The AP600 never found a buyer. Suprise, surprise… economies of scale still mattered, and six hundred megawatts simply did not produce competitive power prices. The safety case, however, was a breakthrough.

By scaling AP600 up to roughly eleven hundred megawatts without enlarging the containment footprint, Westinghouse produced the AP1000. The diameter of the AP600 and AP1000 containment buildings is the same. Only the height and internal arrangement change. That is a rare case in this sector where scaling laws moved from conference papers to concrete.

The real novelty lies in how the AP1000 handles two categories of accidents that define any PWR’s safety philosophy: loss of coolant accidents, and station blackouts.

LOCAs without a race against the diesels

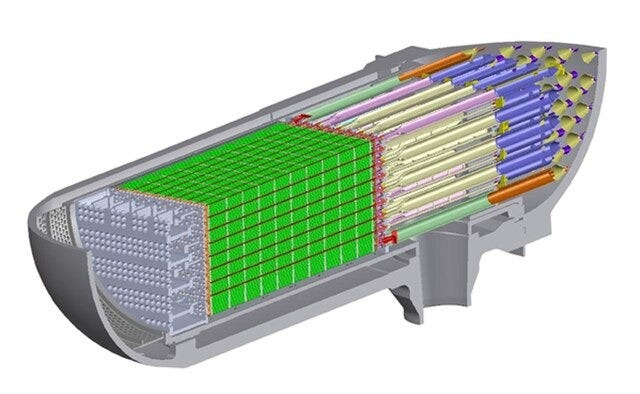

In a classical generation two pressurized water reactor, a large break loss of coolant accident is analysed as a race.

Lets walk through a hypothetical large guillotine break LOCA in a Gen-2 PWR. In this modelled scenario there is a complete severing of a hot or cold leg in the primary circuit. Primary pressure, initially around 2200 psi, collapses in seconds as water flashes to steam and vents into containment.

Nitrogen backed accumulators open automatically as the primary pressure falls below their setpoint, dumping borated water into the core region.

Within about ten seconds, high pressure safety injection pumps must start, powered from safety grade diesel generators that themselves must start, load, and sequence in very tight timelines.

Small and intermediate break LOCAs are more subtle. The leak is slower. Primary pressure falls more gradually and may never reach the accumulator setpoint in time. For those events, operators lean heavily on high head safety injection that requires AC power. If that power is lost, failures in seals on reactor coolant pump shafts can transform a station blackout into an unplanned LOCA of its own.

The AP1000 architecture is designed to remove as much of this race as possible. A few elements are central.

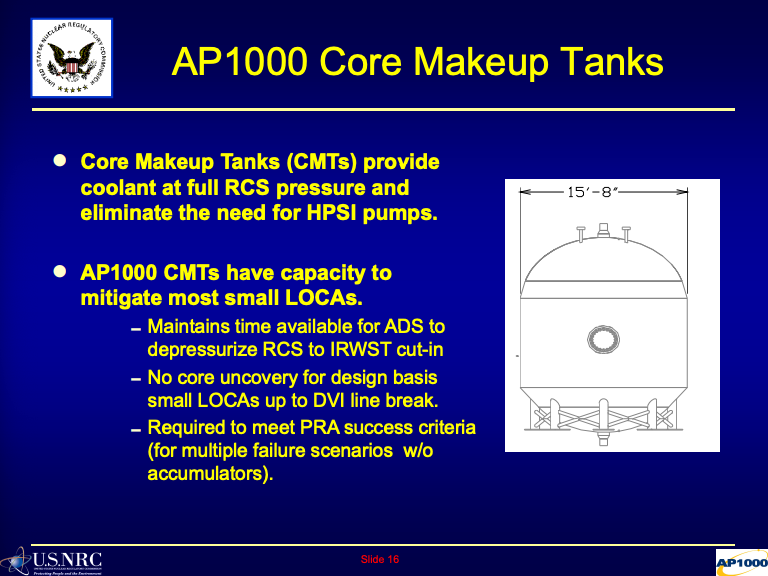

Core makeup tanks at system pressure

In addition to conventional accumulators, which sit at seven or eight hundred psi and only inject once the primary depressurises that far, the AP1000 uses core makeup tanks. These are small borated water tanks kept at primary system pressure, 2200 PSI, through direct communication with the pressure vessel through a cold leg.

In a small or medium break LOCA, they can begin injecting inventory into the vessel as soon as valve actuation logic demands it, long before the accumulated nitrogen tanks would open. No motor driven pump is required, only valves and the pressure differential created by the leak itself.

Automatic depressurisation and gravity feed from inside containment

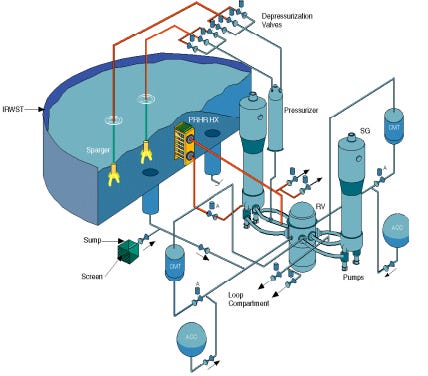

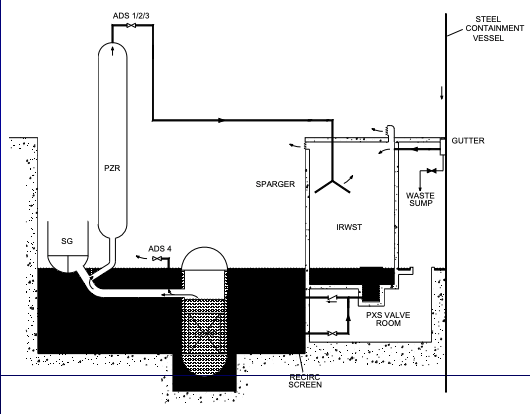

If the system pressure does not fall fast enough, the automatic depressurisation system vents steam in stages from the pressuriser into a large pool of water inside containment, the in containment refuelling water storage tank (IRWST).

As pressure drops, the conventional accumulators open. When the primary is sufficiently depressurised, gravity from that same internal tank starts feeding water into the core region through dedicated injection lines. In later phases, water that has collected in the containment sumps is recirculated.

The key point is that all of this can proceed without safety grade AC. Motor driven injection is replaced by tanks, check valves, and height differences.

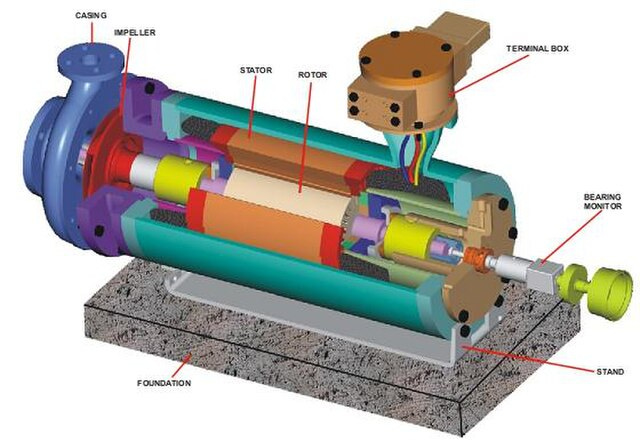

Canned pumps instead of seal packages

The AP1000 adopts canned reactor coolant pumps. Rather than a shaft penetrating a pressure boundary and relying on a complex seal package that itself needs injection flow during a blackout, the motor and impeller sit inside a common pressure housing.

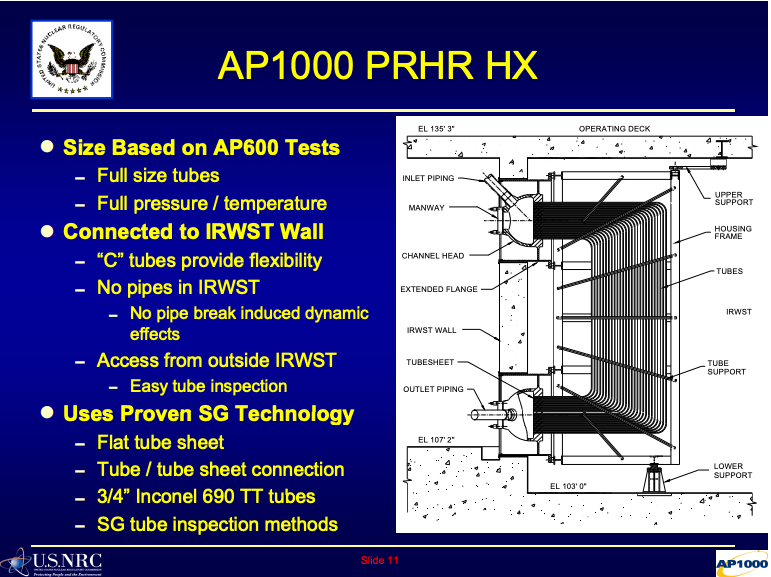

Passive Residual Heat Removal (PRHR)

A final piece of the AP1000’s strategy for gaining 72 hours of operator free cooling in the race-against-residual decay heat time is the Passive Residual Heat Removal heat exchanger, the PRHR.

In a Gen-2 PWR, once the reactor trips on a LOCA or a station blackout, decay heat must be removed through active systems: auxiliary feedwater pumps, motor-driven residual heat removal pumps, and safety-classified cooling water systems. All of those depend, directly or indirectly, on AC power.

The AP1000 replaces that entire architecture with a submerged, naturally circulating heat exchanger, the PRHR, inside the In Containment Refueling Water Storage Tank (IRWST.)

When the reactor trips, hot primary coolant rises by natural convection through the PRHR loop, transfers heat into the large in containment water tank, and flows back down into the primary. There are no pumps, no diesels, and no operator actions in the time-critical window. The IRWST then vents this heat into containment as steam, which is ultimately rejected to the atmosphere through the passive containment cooling system.

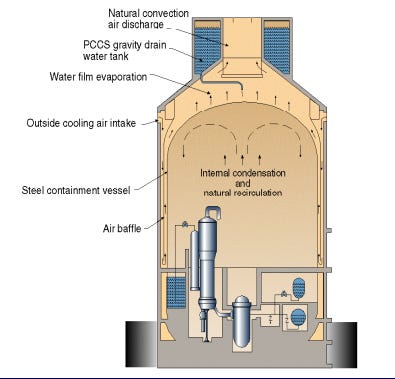

A containment that behaves like a heat exchanger

Every watt of decay heat has to go somewhere. In Generation II plants, that usually means cooling towers or essential service water circuits that feed containment spray systems and residual heat removal exchangers. Those are active systems. They depend on pumps and on external water sources.

Here the AP1000 philosophy diverges completely.

In an accident, steam from a LOCA or from the passive residual heat removal (PRHR) heat exchanger fills the steel containment vessel. That vessel sits inside a separate concrete shield building, with an annulus between the two that is open to the atmosphere at the top.

On the roof of the shield building is a large tank of water. When passive containment cooling actuates, this water is released and flows over the outside of the steel shell as a thin film. Air drawn up through the annulus picks up the heat of evaporation and carries it away. The containment literally sweats. Gutters and downcomers collect part of the water and return it to internal storage.

The effect is to turn the containment shell into a giant vertical heat exchanger, transferring decay heat from the internal steam atmosphere to the outside air, using only gravity and natural draft. The system is sized to operate for seventy two hours without any AC power.

None of this is easy to calculate. Getting film condensation, natural convection, and complex three dimensional flows right in a safety analysis is non trivial. That is why the AP600 and AP1000 programmes included extensive integral test facilities and produced thick NUREG reports on scaling.

Once validated, however, the operating principle is simple. There is no dependence on safety grade AC and no need for safety classified cooling towers or ultimate heat sinks in the classical sense. The ultimate heat sink is the atmosphere itself, a far more elegant solution than say NuScale’s VOYGR plant which relies on what is probably one of the most heavily engineered and seismically qualified bathtubs on earth, a 75 foot deep, ten million gallon nuclear swimming pool in which the reactor modules are semi submerged.

Regulation did not stand still

A recurring line in Western nuclear commentary claims that the Nuclear Regulatory Commission still regulates reactors as if it were the late 1960s, unable or unwilling to accept passive concepts.

The AP1000 designs is a direct refutation.

This reactor could not have been licensed under the standards applied to the early fleet. The elimination of emergency diesels, the replacement of active spray systems with a passive containment cooling tank on the roof, and the heavy reliance on natural circulation for decay heat removal required entirely new validation methods and new rulemakings.

The Department of Energy funded the test facilities. Westinghouse and academic partners built and ran them. The NRC wrote new frameworks for how to treat passive safety systems, how to integrate them into probabilistic safety analysis, and how to credit them in the face of model uncertainty.

One can debate whether the broader licensing system is efficient. What cannot be claimed with a straight face is that nothing has changed. The AP1000 is concrete proof that the regulator will accept novel safety architectures when they are backed by data.

Startups, technology readiness, and the limits of imagination

Most of the new companies pitching reactors in the West do not grasp the gulf between a credible safety case built on thousands of operating years and a set of simulations with limited test data.

Their slides often promise first commercial units this decade, at costs comparable to combined cycle gas, with construction schedules measured in two or three years and ninety percent capacity factors implied from day one. They assume worry-free cold and hot functional testing of their FOAK reactors as if they were a software alpha release.

The historical record for first of a kind nuclear plants suggests something different. Even with conservative design choices and large engineering teams, early years are often spent working through valve issues, instrumentation quirks, and thermal hydraulic surprises. Scaling factors that looked benign on paper reveal themselves. Capacity factors start low and climb only with time.

The AP1000 is not exempt from that history. Its first projects were late and over budget, largely due to civil construction and supply chain issues. What is notable is that once those units were completed, they behaved as they should like the light water reactors with familiar components that they were based on. They produced high capacity factors quickly because their cores, steam generators, and pumps were evolutionary, not revolutionary.

Westinghouse did not innovate in the parts of the plant that have to work flawlessly every day just to make steam. They did innovate in the parts that only matter in rare accidents, where simplicity and passivity can remove whole classes of failure.

What AP1000 tells us about the real “next chapter”

If you strip away the branding, the AP1000 is not the future of nuclear in the sense that a marketing department uses that word. It is the logical endpoint of a specific light water reactor tradition.

It retains a conventional nuclear steam supply system, drawn from the best of Westinghouse and Combustion Engineering practice. It layers on top of that a safety system that assumes a station blackout from the outset, relies on tanks, gravity, and natural circulation, and removes most of the time critical AC dependencies that defined earlier designs.

It exists in the real world. It has units in operation in China and the United States. It has an industrial base that knows how to build its core components. It has a regulator that has already worked through the hardest questions of its safety case.

In a power system where the scarce commodity is no longer cheap electrons at noon but firm, clean megawatt hours at three in the morning, that combination matters far more than novelty.

If the use cases are sufficiently economically compelling, a big if, the “next chapter” for American nuclear power may eventually branch into so-called “advanced reactors.” These previously explored technologies failed to operate reliably and economically last century but with massive multibillion dollar R&D may at some point prove themselves. But the pages for the foreseeable future are being written by a nuclear steam supply system that looks, at first glance, almost disappointingly familiar.

Please support our work

If you have made it this far, you are part of a very select species, the kind of person who voluntarily spends their free time thinking about core makeup tanks, double-ended guillotine breaks, and the thermal hydraulics of a steaming steel egg.

You are why Decouple exists. Truly. My condolences.

If you want more long-form, empirically grounded work that prefers test loops and scaling laws to pitch decks and pastel-coloured microreactors, you can help keep this whole operation supercritical:

Become a paid subscriber. It keeps the microphones on and the reactor schematics flowing.

Share this piece with the friend who still thinks “advanced nuclear” means concepts generated and attempted 70 years ago.

Like and comment so I know what subsystem to dissect next, civils, fuel, or the geopolitics welded to all of it.

Support Decouple Media if you want a nuclear conversation anchored not in imagination, but in the reactors that actually exist and work.