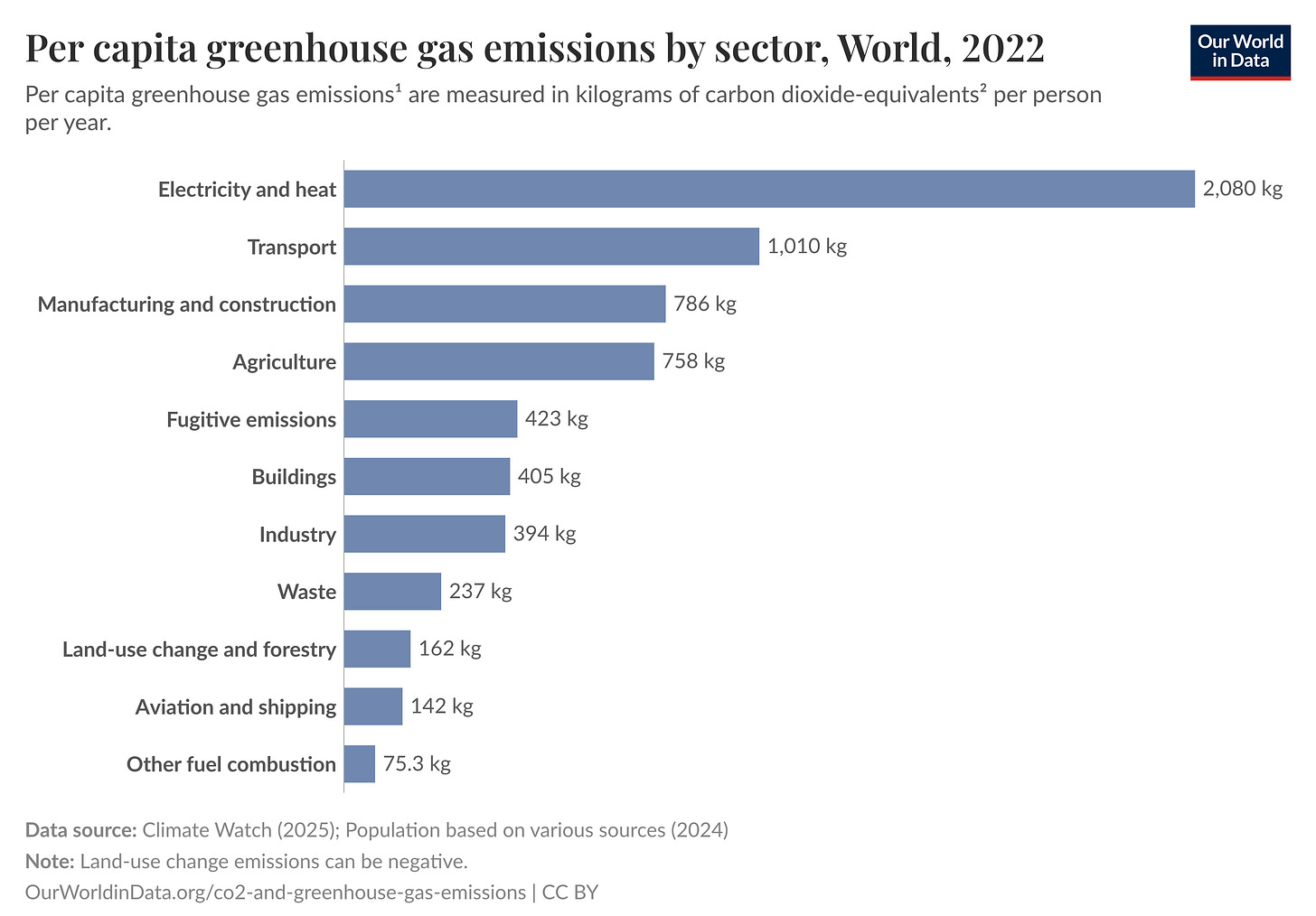

Process heat accounts for two-thirds of industrial emissions which in turn make up 25% of global carbon emissions. Yet talk of decarbonization often misses the engineering realities that separate viable solutions from expensive dead ends. To understand process heat and the technologies capable of providing it, I’m joined by returning guest Jesse Huebsch, a process engineer specializing in chemical plants. Our conversation ranges from steel and cement to plastics and ammonia, examining which processes can be electrified, where steam dominates, and why the most advanced high-temperature reactor designs may not be a panacea.

Watch now on YouTube.

We Talk About

What process heat actually does: driving endothermic reactions and phase changes

Steel production pathways from blast furnaces to direct reduction of iron, and the role of hydrogen

Why ethylene cracking presents unique challenges for nuclear heat application

The underappreciated potential of oxygen intensification for high-temperature processes

The engineering and economic barriers to co-locating reactors with chemical facilities

China’s hybrid approach: pairing conventional reactors with high-temperature gas reactors

Why peak heating demand shapes the entire energy system

Deeper Dive

In broad terms, about a quarter of global emissions come from industry, with two-thirds of that from the production and use of process heat, representing some 10 or 11 gigatons of CO2 annually. But process heat is not some bulk commodity. It is a service that must be precisely tailored on-site to an incredible array of industrial and chemical processes.

Every single part of [using process heat] has its own wrinkles and complications. Every process has its own unique twists to it. That’s what makes it both challenging and worthwhile. — Jesse Huebsch

Take steel production. Traditional blast furnaces use coking coal to make carbon monoxide, which both provides the reducing agent and generates enough heat to melt the product. The emerging alternative—direct reduction of iron (DRI)—uses hydrogen or natural gas-derived syngas as the reducing agent at lower temperatures, producing solid iron that’s then melted in electric arc furnaces. Huebsch notes that significant amounts of steel (5–7% of global production) are already made via DRI, mostly using natural gas rather than pure hydrogen. Thus, the shift to green hydrogen isn’t a leap into unknown technology but a gradual fuel substitution in processes that already exist.

Where do high-temperature gas reactors fit into process heat? Unfortunately, it might not be the perfect match often advertised. Gas-to-gas heat transfer requires enormous, expensive heat exchangers made from exotic “unaffordium” alloys at scale. Multiple loops are needed to keep radioactive primary coolant separate from process vessels. Most critically, these reactors would need to be sited within hundreds of meters of chemical facilities, placing them within the blast radius of industrial accidents that, as Huebsch points out, have killed far more people than nuclear accidents ever have.

For nuclear process heat, conventional water-cooled reactors producing steam at 300°C can already address many industrial heat needs. Steam moves smoothly through pipelines (China is already exporting some 500 megawatts of medium-pressure steam to a petrochemical complex through a pipeline tens of kilometres long). Additionally, the heat exchangers are orders of magnitude smaller, using conventional stainless steels. For ultra-high temperature needs, one of Huebsch’s “most underappreciated tricks” is using plain electricity to run air separation units, then using pure oxygen to intensify combustion—potentially reducing fuel needs twentyfold.

“The vast majority of heat needs can already be covered by water-cooled reactor output temperatures. You’re getting into the more specialty uses as you go to higher temperatures than that.” — Jesse Huebsch

The timeline for decarbonizing process heat stretches longer than many hope. Industrial facilities have 50 to 80-year lifespans, and retrofitting is hard. The real opportunity lies in building new facilities with future decarbonization in mind.

To Huebsch, the real heat-related decarbonization question comes down not to process heat, but to overall “peak heating,” including commercial and residential demand. “However we deal with that will shape what a decarbonized energy system looks like, because any system that can deal with that peak heat then has all of the elements it needs to deal with pretty much any other conditions.”

Watch the full interview:

Support Decouple

If you find our work valuable, consider supporting Decouple by pledging on Substack or making a tax-deductible donation through our fiscal sponsor at Givebutter.

Note: This post was made with the help of modern AI.