Microreactors and Diesel Generators

Category Errors in Nuclear Energy

Human beings rely on mental models drawn from familiar domains to help us make sense of novel phenomena. While this cognitive shortcut can be useful, it leaves us vulnerable to category errors—mistakenly applying the wrong conceptual framework to a new or fundamentally different system. Nuclear power is particularly prone to this phenomenon and in today’s essay I’m going to put one such category error under the microscope.

Nuclear microreactors are increasingly touted as a promising replacement for diesel generators. The appeal is understandable: clean, continuous power, delivered in factory-built, plug-and-play units capable of serving remote mining sites, off-grid communities, and even data centers operating behind the meter. Yet, aside from their small power outputs, microreactors share very little in common with diesel generators.

The Diesel vs. Microreactor Faulty Comparison

Scaling diesel engines from a 5 kW home generator to a 100 MWe marine engine presents some challenges but is mechanically feasible. Compression ignition, modular engine components, and relatively simple infrastructure allow diesel engines to economically span four orders of magnitude in power output.

In contrast, nuclear microreactors struggle to scale down due to unavoidable inherent costs—radiation shielding, neutron chain reaction limitations requiring expensive fuel, complex operations and maintenance (O&M), spent-fuel handling, licensing, and regulation.

Unlike a diesel engine, shrinking a reactor’s size does not yield proportional cost savings; instead, it increases the cost per unit of power.

Shielding: A Non-Negotiable Inherent Cost

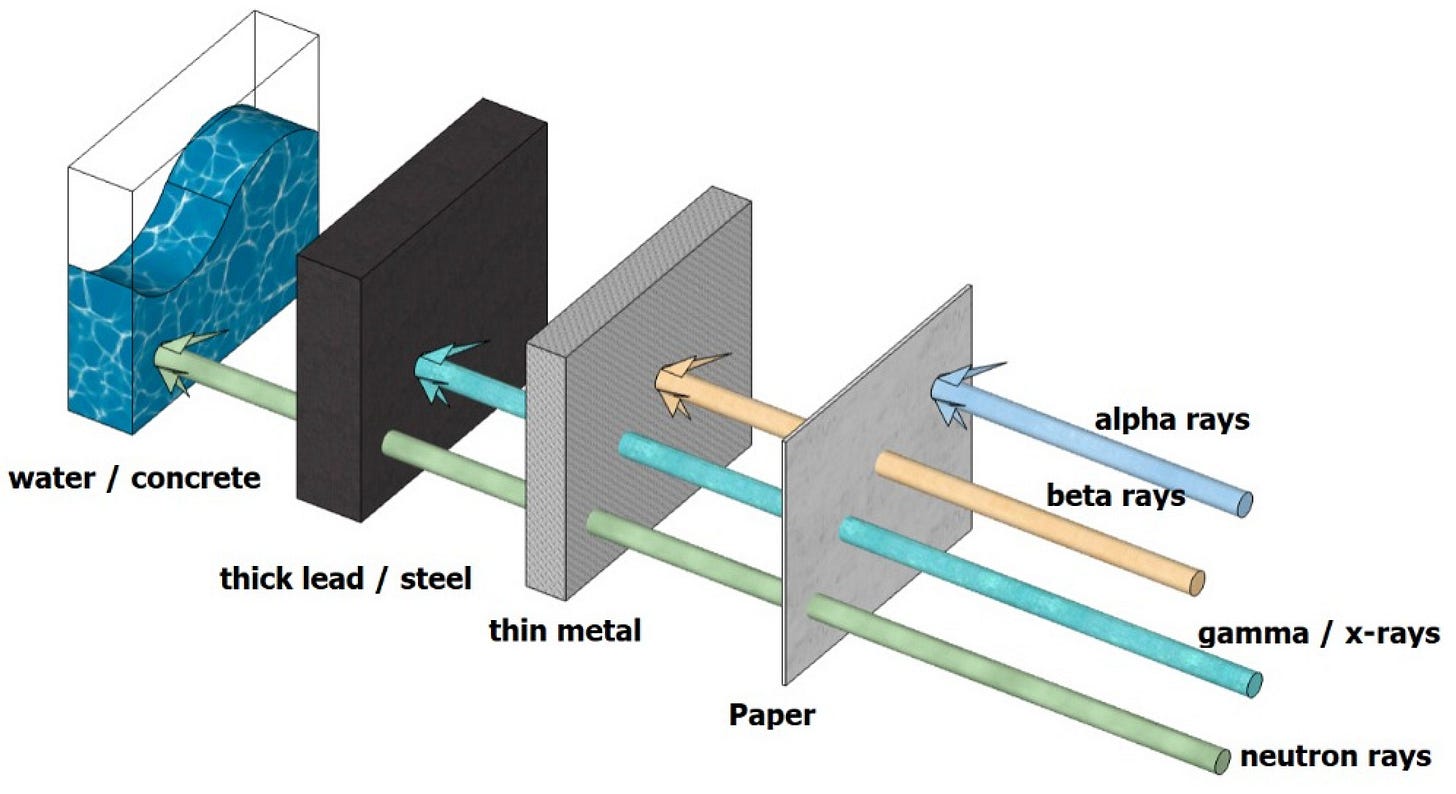

A fundamental difference between diesel and nuclear power generation is radiation. While diesel generators emit pollutants, they do not produce radiation. Even low-power nuclear reactors, however, emit dangerous levels of radiation that require extensive shielding to protect personnel and the environment.

This reality is illustrated by two of the world’s first nuclear reactors:

Chicago Pile-1 (CP-1) operated at roughly two watts with no shielding, solely to demonstrate a controlled chain reaction.

Chicago Pile-2 (CP-2) ran at just two kilowatts—enough to power a couple of toasters—yet produced a radiation dose of about 300 millisieverts per second, enough to deliver a fatal dose in under a minute. Consequently, five feet of concrete shielding were installed to protect personnel

.

Despite their smaller size, microreactors still require thick, often immovable shielding. Their compact cores place radiation sources and maintenance areas in close proximity, complicating repairs and exposing workers to higher doses if internal maintenance is required.

The Physics of Neutron Economy

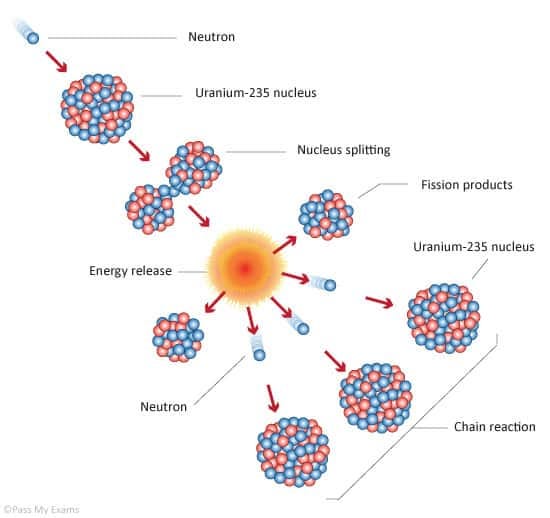

Another fundamental challenge for small-scale reactors is neutron economy—the balance of neutrons produced, absorbed, and lost. Fission releases energy and free neutrons, which must collide with uranium-235 atoms to sustain the chain reaction. Neutrons can be absorbed by non-fission materials (“neutron poisons”) or escape the reactor entirely.

Larger reactors benefit from a favorable surface-area-to-volume ratio. The neutrons they produce are more likely to find a dancing partner. In contrast, microreactors, with a higher surface-area-to-core-volume ratio, generate a lot of lonely neutrons.

Historically, "bomb grade” highly enriched uranium (HEU) was used to compensate for poor neutron economy in small reactors, but HEU is heavily restricted due to proliferation risks. Modern microreactors typically use High-Assay Low-Enriched Uranium (HALEU), less enriched than HEU but still far more expensive and scarce than traditional low-enriched uranium (LEU). While neutron reflectors can help, they add complexity and size and do not fully solve the leakage problem. These physical constraints drive up costs at smaller scales, unlike diesel generators, which can be downsized or upsized with relative ease.

Fuel Costs: The HALEU/TRISO Supply and Demand Challenge

HALEU production is costly and currently concentrated in Russia. Only a few facilities worldwide are licensed to produce it. The result: HALEU is expensive because it is not produced in bulk, and it is not produced in bulk because it is expensive.

For example, Westinghouse’s 5 MWe eVinci microreactor requires an estimated metric ton of HALEU fabricated into a special meltdown-proof fuel called TRISO. In 2023, the U.S. produced only about 20 kilograms of HALEU, at a cost of 60 million or $3,000,000/kg. There were aspirations to scale up to 900 kilograms in 2024—still far below what is needed for widespread deployment—which unfortunately were not achieved.

U.S thinktank Third Way estimates that if a 3.9-4.4 billion program investment is made, the cost of HALEU could come down two orders of magnitude to $32,600 per kilogram. At that price fueling a single 5 MWe eVinci microreactor for its 10 year run could cost north of $32 million. Even if a “microreactor gigafactory” could manufacture the reactor for free, the cost of that initial fuel load, a defacto capital cost, threatens commercial viability.

By contrast, a 5 MWe diesel generator costs $1–$2 million upfront. While diesel fuel represents a significant cost, it accrues gradually as an operational expense.

The Catch-22 of Factory Production

Microreactor proponents argue that mass production will eventually reduce costs, drawing parallels with industries like automotive manufacturing, where high order volumes enable efficient, low-cost assembly.

However, the same inherent costs—shielding, specialized fuel, neutron reflectors, and regulatory compliance—persist at micro scales. Will enough customers pay a 10–100× premium over a diesel generator to justify investing in the microreactor gigafactories and fuel fabrication infrastructure necessary to drive down costs? If not, early units must be custom-built, making them expensive and getting a true sense of N-th let alone 100-nth of a kind cost will remain highly speculative.

Operations, Maintenance, and Spent Fuel Handling

Maintaining a diesel generator requires technicians with mechanical expertise, which are widely available; no health physicists are needed to manage radiation risks. In contrast, nuclear reactors—including microreactors—require specialized personnel even for routine tasks.

Consider spent fuel handling. While civilian nuclear waste is perhaps the best managed waste stream of any power generation technology, its perfect safety record depends on strict protocols. In large reactors, refuelling occurs under one roof and the associated costs are amortized over thousands of gigawatt hours. In microreactors, however, high inherent costs—cranes, casks, radiation monitoring, specialized training, secure on-site storage or packaging for transportation to a centralized facility—must be repeated for each unit. In addition, most microreactor concepts being explored currently are non–water-cooled reactors, which makdes spent-fuel handling even more complex, as water is a particularly convenient radiation shield.

Lessons from Naval Reactors

Around 250 microreactors are currently in operation in specialized naval applications, such as submarines, aircraft carriers, and icebreakers. Submarines equipped with 30–60 MWe reactors can remain submerged indefinitely and maintain incredible underwater speeds, an unparalleled advantage for ballistic missile and fast-attack missions. Even so, diesel-electric submarines outnumber nuclear submarines 4 to 1, and a nuclear powered merchant marine never emerged as nuclear propulsion remains expensive and logistically complex.

A Genuine Niche is Hard to Find for Land Based Microreactors

Despite high logistics costs at remote outposts—even in Antarctica—diesel generators have historically been cheaper and more manageable than microreactors. This is not to say that innovation cannot improve microreactor economics. In niche cases, such as military applications where supply lines are vulnerable or fuel costs are extreme, microreactors may justify a the cost and logistics premium.

But will demand be high enough and orderbooks deep enough to support the microreactor gigafactories and specialized fuel facilities needed to make them economically viable for near term commercial use?

Its time to put this category error to bed. Microreactors are not the nuclear equivalent of a diesel generator. Their inherent costs—shielding, specialized fuel, neutron economy, and regulatory burdens—inflate per-kWh expenses as reactor size decreases. While unique applications such as naval propulsion and space exploration justify these costs, there is little evidence that land based microreactors can outcompete diesel generators in all but the most extreme circumstances.

A decade of small-reactor enthusiasm has overshadowed a hard truth: economies of scales are a cruel master of nuclear power, more so perhaps than any other form of power generation.

For a deeper dive on this topic check out my conversation with Nick Touran on the Decouple Podcast.

Chris, Really clear article dealing with facts, not hopes.

Really fantastic write-up, have already sent it along to friends who have had questions on the subject!